This particular Winchester Model 20 is Serial Number 10981. The information below describes and shows the correction and preservation operations performed on this shotgun.

The photos below show the gun before preservation:

There are no damaged, broken, or missing parts. Current Condition

None of the metal is dented, bent, cracked, or broken and no metal repairs have been made. Much of the exposed metal, especially on the receiver, is covered with surface rust with some pitting and some original blueing remains. Virtually all of the unexposed metal is in excellent condition with virtually 100 percent of the original blueing remaining.

None of the wood is cracked or broken and no wood repairs have been made. The stock and forend appear to have been poorly revarnished because much of it has flaked or rubbed off. There are no missing sections, gouges, deep scratches, or dents in the wood.

Apparently, the gun has had very little use because the action is very tight, the bore is in excellent condition, and none of the screws show the slightest bit of damage or wear.

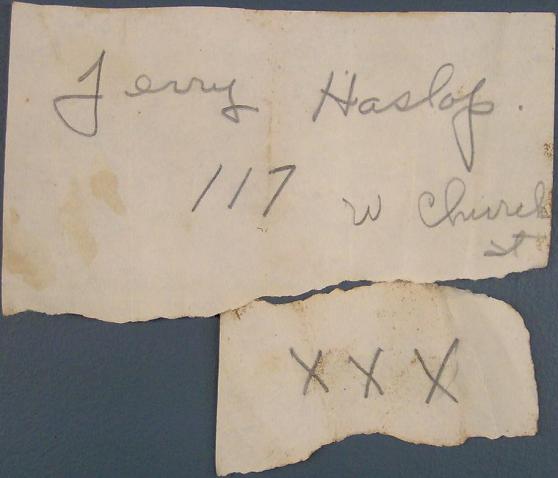

The note below was found curled up inside the stock after the butt plate was removed:

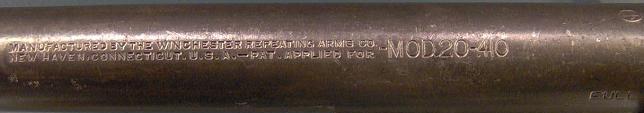

The photos below show the barrel before gently cleaning, after gently cleaning, and after blueing as described at Blued Metal Cleaning: Metal Correction and Preservation

Before Gently Cleaning

After Gently Cleaning

After Blueing

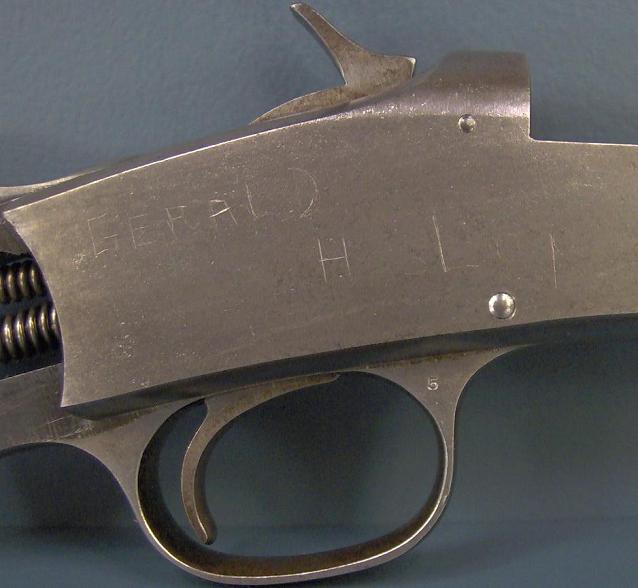

While gently cleaning the receiver as described at Blued Metal Cleaning, it was discovered that the name "GERALD HASLOP" had been scratched in the metal of the receiver as shown in the photo below:

There was no clue this damage existed till after the receiver was gently cleaned. Because the goal is to preserve the gun, the damage of the scratched receiver is removed by block polishing with 600 and then 800 grit sandpaper, just enough to remove the damage, followed by polishing with fine steel wool. The result is shown in the photo below:

The receiver was then blued as described at Blueing using 5 applications of Paste Blueing. The result is shown in the photo below:

After curing for one week, the Paste Blued metal was rubbed with fine steel wool to determine how durable the Paste Blueing is and to confirm that all of the scratched name damage was indeed removed. It was observed that the Paste Blueing is not nearly as durable as the manufacturer leads one to believe. The photo below shows the receiver after virtually 100 percent of the blueing was removed with fine steel wool after having cured for one week:

The receiver was then blued as described at Blueing using 3 applications of Liquid Blueing. The result is shown in the photo below:

The photos below show the stock with forend before and after finishing as described at Stock Oil/Varnish Finishing. There was no residual oil to remove: Wood Correction and Preservation

Before Finishing

Finishing Details 1. Strip with Paint And Varnish Remover

2. Block sand with 320 through 800 grit sandpaper

3. 10 applications of Oil/Varnish:

A. 3 Oil/Varnish applications

B. Sand with 400 grit sandpaper

C. 2 Oil/Varnish applications sanding between each with 600 grit sandpaper

D. 2 Oil/Varnish applications sanding between each with 800 grit sandpaper

E. 3 Oil/Varnish applications rubbing between each with fine synthetic wool

After Finishing

The Results

Before

After

Before

After

Before

After