This gun makes an excellent demonstration example because the stock is made of Maple, a light colored wood, and will show color variations well.

The forend shown below will be finished to match the factory finish as close as possible using a single readily available stain and a polyurethane finish:

Refer to Wood Staining for more information on staining wood. To prevent any possible compatibility issues, the stains and finishes of a single manufacturer will be considered; in this case Minwax. The product directions are followed precisely.

The Winchester Model 37A is advertised as having a "walnut finish" stock. After final sanding, the factory first applies a pre-finish coating to produce a uniform color. The factory then applies what appears to be a laquer finish that contains a redish-brown stain. This results in a finish that is relatively uniform and consistent but hides much of the wood grain texture. Since the intent of the gun manufacturer was to have the gun stock appear as one made of Walnut, the following stains are included in this demonstration. Stain Options

These applied stains will be shown in the order given above from left to right in the photos.1. Walnut (Gel, 606)

2. Provincial (211)

3. Special Walnut (224)

4. Dark Walnut (2716)

5. Jacobean (2750)

6. Red Mahogany (225)

7. Brazilian Rosewood (Gel, 608)

Normally, finish matching is performed using a sample piece of the species of wood the gun stock is made of having a similar grain pattern. However, because a factory pre-finish coating exists on many gun stocks, the factory original forend is used in this demonstration. This forend was first stripped using both stripping methods described at Gun Stock Stripping. This was done to demonstrate matching the factory finish when the factory pre-finish coating is removed and when it is not removed.

Wood Preparation

The photo below shows the forend after stripping at Gun Stock Stripping:

Notice that the right side of the forend (top portion in photo) was stripped with Paint And Varnish Remover and the left side of the forend (bottom portion in photo) was stripped with Oven Cleaner (e.g. EASY-OFF). As can be seen, the Paint And Varnish Remover (methylene chloride also called dichloromethane) did not remove the factory pre-finish coating. The Oven Cleaner (sodium hydroxide) did remove the factory pre-finish coating but damaged wood fibers and caused the wood to turn darker.

The photo below shows the results after sanding the forend with 320 and then 400 grit sandpaper.

Notice that the darkened wood, caused by stripping with Oven Cleaner, exists at a depth slightly greater than the depth of the factory pre-finish coating.

The photo below shows the results soon after applying Pre-Stain Wood Conditioner to the side of the forend that the factory pre-finish coating was removed from:

Finish Comparisons

Two applications of stain are applied to each side of the forend (above and below the checkering), from left to right in the photos, as follows:

The photo below shows the results after staining and three Linseed Oil/Varnish Finish applications:1. Walnut (Gel, 606)

2. Provincial (211)

3. Special Walnut (224)

4. Dark Walnut (2716)

5. Jacobean (2750)

6. Red Mahogany (225)

7. Brazilian Rosewood (Gel, 608)

The photo below shows the forend next to the factory finished stock being matched to. Note that the photo below was reversed to keep the stain orders proper from left to right and, therefore, the left side of the stock is actually being viewed.

It appears that the stain matching closest to the factory finish is the Red Mahogany (225) penetrating stain. However, as demonstrated in Wood Staining, Maple does not absorb stain evenly and can produce blotchy results. Therefore, the Brazilian Rosewood (608) gel stain is used.

Forend Finishing

The photos below show the forend after being stripped (again) and then sanded with 180 grit sandpaper:

The photo below shows the forend after having the grain raised followed by two applications of Brazilian Rosewood (608) gel stain to acquire the redish color of the factory finish:

To produce a color, gloss, and texture to match the factory finished stock, Minwax PolyShades (Stain and Polyurethane) Antique Walnut Gloss (440) is then applied. Note that Minwax PolyShades is a polyurethane that includes a stain and must be applied in very thin coats. Antique Walnut Polyurethane/Stain was chosen to acquire the brown color of the factory finish. The gloss polyurethane finish should be somewhat more durable than the laquer factory finish and will produce a sheen that is very similar to that of the factory finish.

The photo below shows the finished forend above the factory finished stock. Nine (very thin) applications of PolyShades Antique Walnut Gloss (440) were required to match the factory finish:

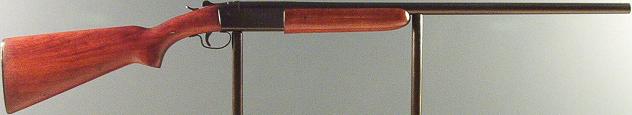

The photo below shows Winchester Model 37A Shotgun serial number C523878 after assembly:

Winchester Model 37 Example

The Winchester Model 37 (1936-1963) in this example is believed to have a Birch stock. A Boiled Linseed oil finish is used to match that of the factory stock finish. The photo below shows the forend after being finished with 3 applications of Red Mahogany (225) stain followed by 5 applications of Boiled Linseed Oil above the factory finished stock.

The photo below shows the Winchester Model 37 Shotgun after assembly: