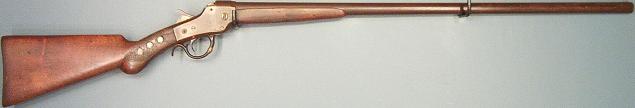

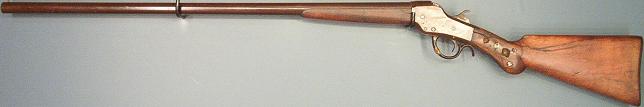

This gun makes an excellent demonstration example because the stock is checkered and has had multiple bad repairs using the following six (6) fasteners, some of which had been covered with wood putty:

1. One (1) Nail

2. Three (3) Bolts

3. Two (2) Wood Screws

The gun is shown in the photos below:

The photo below shows the nuts of the 3 bolts used in the repairs:

The photos below show before and after the wood putty was removed that had covered the fasteners. Also notice the mutilations around the middle bolt.

The photo below shows the section after removing the fasteners and separating the broken parts:

Notice that the wood contains much embedded oil.

The photo below shows the section after soaking in Mineral Spirits for 12 hours, brushing with a fine bristled nylon brush, vacuuming, and then drying for 12 hours:

The photo below shows the section after soaking in Mineral Spirits a second time for 12 hours, brushing with a fine bristled nylon brush, vacuuming, and then drying for 12 hours:

The photo below shows the section after soaking in Mineral Spirits a third time for 12 hours, brushing with a fine bristled nylon brush, vacuuming, washing in Murphy's Oil Soap three times 2 hours apart, and then drying for 12 hours:

To make a strong permanent repair, dowel rods of the same species of wood as the stock will be used with the grain running perpendicular to the grain at the break. The holes where the fastener heads existed and where dowel rods ends show will then be plugged with wood of the same species of wood as the stock and having a color and grain pattern that matches that of the stock as much as possible. The grain of the plugs will run parallel to the grain of the stock (i.e. perpendicular to the dowel rod grain). Note that the dowel rods will not extend all the way through the stock and the wood plugs will cover the dowel rod ends.

Gorilla Glue is used because it is very strong and waterproof. Refer to Gorilla Glue Web Site for details. Read, understand, and follow the Gorilla Glue directions.

The photo below shows the glued stock along with two pieces of Walnut. These pieces of Walnut were selected from many boards to acquire those which best match the color and grain pattern of the damaged portions of the stock to be plugged. Mineral Spirits have been applied to the top half of the pistol grip section of the stock and the top half of the Walnut to show the approximate color of the wood after being finished.

As can be seen in the photo above, it appears that the color and grain pattern of the piece of Walnut on the right side matches that of the stock the best.