The photo below shows the products normally used to prevent rust:

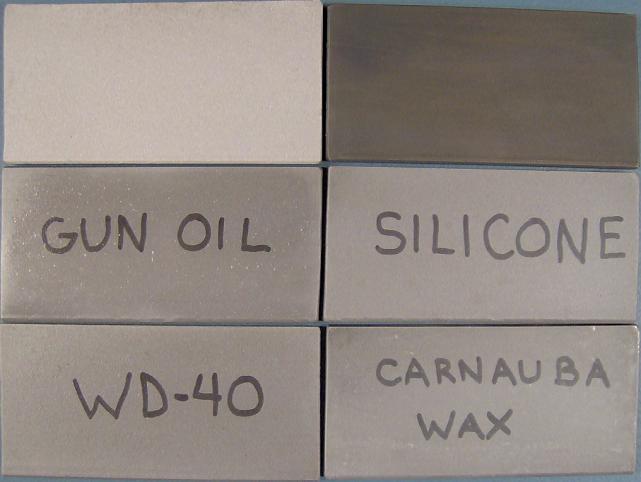

The photo below shows 2" by 4" by 1/4" pieces of steel that have been sandblasted and marked with the name of the product used to prevent rust. The top left piece is bare steel and the top right piece has had 3 applications of Paste Gun Blue:

RUST TEST #1

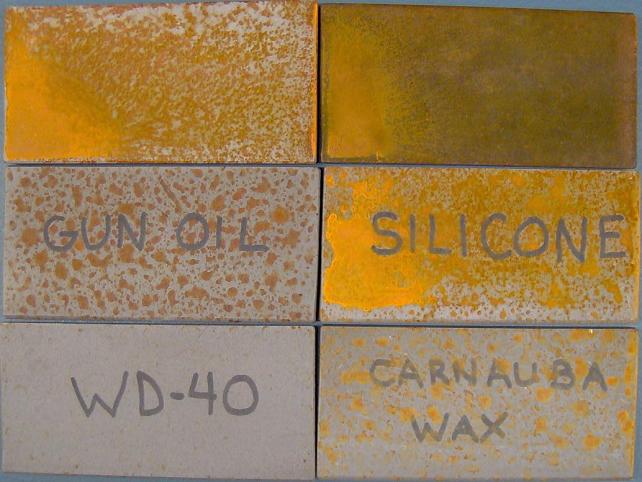

The photo below shows the same objects above after being exposed to outside snow, sleet, and rain for one full week:

The results show that WD-40 is the best at protecting the steel from the outside cold and wet environment.

The author was quite surprised to see the above results. Therefore, a second test is conducted using an environment that is more like the most harsh environment that a gun would be exposed to.

RUST TEST #2

Guns are normally not exposed directly to water but may be exposed to high humidity as well as high temperatures during storage and display. After considering various standardized tests, the author implemented a test based on the Society of Automotive Engineers (SAE) Surface Vehicle Standard, J 2334 Cosmetic Corrosion Lab Test as described at http://www.ascott-analytical.com/SAEJ2334/. This test is performed as follows:

Test specimens are placed in an enclosed chamber and exposed to a changing climate that comprises of the following 3 part repeating cycle:Part 1 of the SAE J2334 test is implemented. An aquarium is partially filled with hot water that is placed above a 60 watt light bulb. The pieces of steel are placed above the heated water in the aquarium. A thermometer is placed in the water to monitor the water temperature and a thermometer and humidity monitor is placed above the water to measure the temperature and humidity the metal parts are exposed to as shown in the photo below:

- 6.0 hours exposure to a water fog/condensing humidity climate of 100%RH at +50C (+122F).

- 15 minutes immersion in (or a direct spray of) salt water at ambient temperature.

- 17 hours 45 minutes of air drying in a climate of 50%RH at +60C (+140F).

After the entire set up is wrapped in reflective bubble wrap, the temperature rises to approximately 120 degrees with a relative humidity of approximately 100% within 2 hours.

The photo below shows the steel pieces after being in the environment for 4 hours and drying for approximately 15 minutes:

The photo below shows the steel pieces after being in the environment for one day and drying for approximately 15 minutes:

The photo below shows the steel pieces after being in the environment for one full week and drying for approximately 3 days:

The results show that WD-40 is the best at protecting the steel from the hot and humid environment.

The photo below shows the same objects above after being exposed to sun, heat, and rain for one full week:

The results show that WD-40 is the best at protecting the steel from the outside hot and wet environment.

The same tests above will be performed with steel that is once again sandblasted but then also sanded with a belt sander to produce a glossier surface.