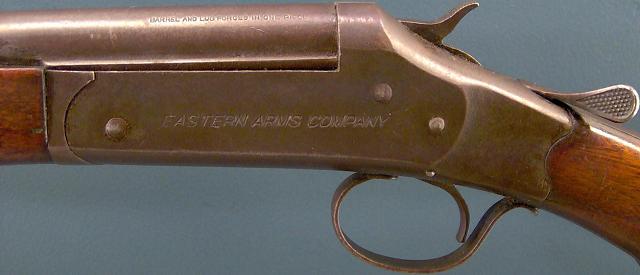

While attending a gun auction, the author flipped forward in the catalog to determine which guns were coming up later to bid on. When the author flipped back in the catalog to the gun currently being bid on, he noticed the gun in the catalog was a Winchester Model 41 shotgun. Realizing that these shotguns are currently worth about $500.00 in the condition of the one at the auction, the author thought he made a wise investment when he agreed to a bid of $150.00 that made him the new owner of the gun. Total cost for the gun came to $170.40 ($150.00 + $10.00 handling fee + $10.40 6.5% sales tax = $170.40). However, the author soon realized that he did not bid on the Winchester, but on an Eastern Arms Company .410 single shot shotgun that he would not have given $10.00 for (literally). To add insult to injury, the author also had to wait several more hours till the FFL (Federal Firearms License) Background Check was completed and approved before he could resume normal activities. The only question that remains is: Who was the other person bidding on this gun who was willing to pay $140.00 plus fees and taxes! Maybe that person too thought they were bidding on a gun other than the Eastern Arms gun?

For those interested, the Winchester Model 41 shotgun eventually sold for $489.90 ($450.00 + $10.00 + 29.90 = $489.90).Internet rumors are that guns like the Eastern Arms Company shotgun were sold during the 1920s through the 1950s and are considered to be a "Hardware Gun" that was made for a hardware store by any one of several major manufacturers. They were marked with names like Eastern Arms Co., Central Arms Co., Western Arms Co., Acme Arms Co., Empire Arms. Co., and so on. The Eastern Arms Company was supposedly a trade name for guns sold by Sears & Roebuck and the shotguns are rumored to have been manufactured by either J. Stevens Arms, Iver Johnson, Meriden Firearms, or Harrington & Richardson (H&R).

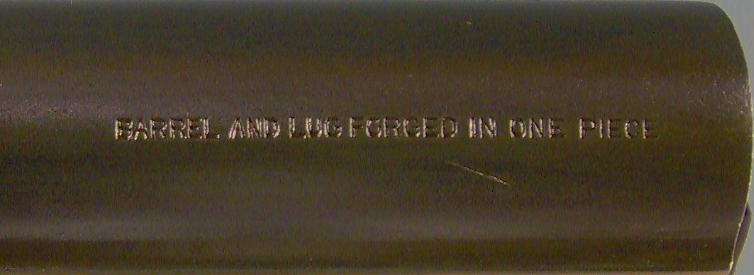

This particular Eastern Arms Company .410 shotgun is Serial Number 57559. The information below describes and shows the correction and preservation operations performed on this shotgun.

The photos below show the gun before preservation:

There are no damaged, broken, or missing parts. Current Condition

None of the metal is dented, bent, cracked, or broken and no metal repairs have been made. The exposed metal has some surface rust with some pitting and some original finish remains. Virtually all of the unexposed metal is in good condition with virtually 100 percent of the original finish remaining.

The wood is cracked in places but none is broken and no wood repairs have been made. The stock and forend appear to have been revarnished because varnish exists on top of small scratches in the wood. There are no missing sections, gouges, deep scratches, or dents in the wood.

Apparently, the gun has had little use because the action is tight and the bore is in excellent condition.

The photos below are of the receiver showing the remaining exposed and unexposed casehardened finish, after chemically removing rust with Blue And Rust Remover, and after blueing with 5 applications of Paste Blueing as described at Blueing Comparison Of Liquid Versus Paste: Metal Correction and Preservation

Before

After chemically removing rust

After Blueing

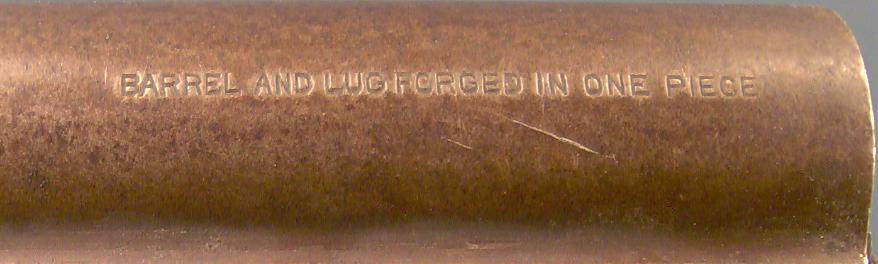

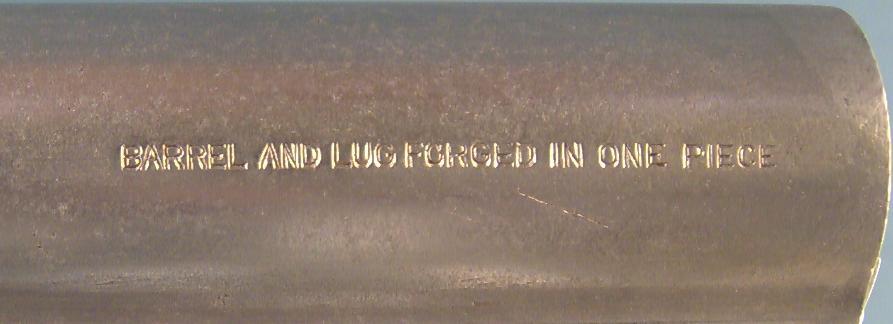

The photos below are of the barrel before, after chemically removing rust with Blue And Rust Remover, and after sandblasting and blueing with 5 applications of Paste Blueing as described at the bottom of Blueing Comparison Of Liquid Versus Paste:

Before

After chemically removing rust

After sandblasting and blueing

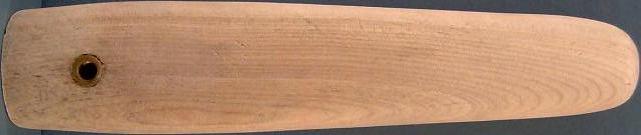

The photos below show the stock with forend after stripping with Paint and Varnish Remover as described at Stock Stripping: Wood Correction and Preservation

The stock and forend contained absorbed gun oil that was removed as described at Stock Boil Oil. The photos below show the forend after the various operations performed on the stock and forend from stripping to finishing:

After stripping and waiting one week to allow oil to seep to surface:

After soaking 1 hour in boiled water, scrubbing with Dawn and waiting several days to allow oil to seep to surface:

After rubbing with Dawn, soaking 1 hour in boiled water, scrubbing with Murphy's Oil Soap, and drying:

After sanding with 320 grit sandpaper, raising grain, staining with Minwax Walnut (606) gel stain, and drying:

After staining with Minwax Brazilian Rosewood (608) gel stain and drying:

After 5 applications of Minwax Wipe-On Poly Clear Gloss Polyurethane sanding lightly between coats with 800 grit sandpaper and synthetic wool:

After 10 applications of Minwax Wipe-On Poly Clear Gloss Polyurethane lightly between coats with 800 grit sandpaper and synthetic wool:

The photos below show the stock and forend after 10 applications of Minwax Wipe-On Poly Clear Gloss Polyurethane sanding lightly between coats with 800 grit sandpaper and synthetic wool:

The Results

Before

After

Before

After

Before

After